Keeping up with technological advances means staying ahead of the pack so you don’t suddenly find yourself redundant, like Holden recently found out in Australia.

Global energy giant Woodside established a collaboration with US space agency NASA after emailing through a video of its operations several years ago.

It led to mutually beneficial partnership with both parties aligned on purpose, problems and opportunities.

It may seem an odd pairing – just how can a Perth-based energy company that exports LNG and a US-based space giant possibly have anything in common?

It’s about operating in difficult and dangerous environments (think offshore gas plants, the moon and Mars) and how robotics can make working in those environments safer.

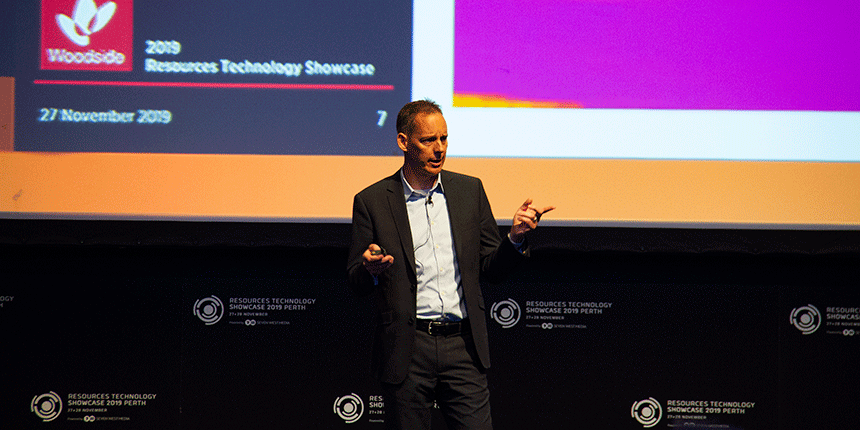

Woodside’s Executive Vice President, Exploration and Chief Technology Officer Shaun Gregory revealed how the partnership is a win-win at the Seven West Media-organised Resources Technology Showcase held in Perth.

As part of the five-year collaboration, a NASA Robonaut – a dextrous humanoid robot – is based at Woodside and is part of its quest to transform its offshore operations by integrating advanced technologies such as robots, sensors and data.

“So for about nine months of the year, and a three-month rotation, a robotics engineer from NASA is working in our lab in Perth alongside Woodside staff,” he said.

“They are working on Woodside opportunities, problems and coding, programming robotics. Importantly, they’re working on Woodside problems, even though they are NASA robotics engineers.”

Gregory said hosting a Robonaut was fascinating, and even though it’s dexterity and hardware is amazing, the smarts sit in the software code, which is transferred and shared jointly with NASA, with a lot of it open source.

“The other opportunity is on Woodside staff seconding over to the Johnson Space Center. And I'll give you an example, the Robonaut with its arms moving and fingers – I think there’s eight in the world. Most of them sit in Houston, one’s on the Space Station until very recently, when it needed to be sent home for repair into Houston,” he said.

“We even had the opportunity to send two of our staff, a field technician from Karratha and an engineer from Perth, to the Johnson Space Center for four to six weeks to assist in the rebuilding of that robonaut before it returns to the Space Station.

“And that is really at the core of where that collaboration is happening. It’s on the people exchange, writing the software, understanding the problems that we have in the industry that we’re trying to tackle to take industry forward and the alignment of those to the space industry.”

When things go wrong on unmanned facilities offshore, Woodside needs to send in a crew by helicopter to undertake the repair.

“A valve needs to be turned, a pump shut off, some very simple maintenance done and our response today is to send some engineers and maintainers in a helicopter, they do the repair, bring them back.

“Not the safest thing for us to do, it’s quite expensive, it would much better if a robot did that.

“Let's go back now to the alignment with the space industry. The next phase of science exploration is a station orbiting the moon on its way to Mars. It will be a manned crew for about one month of the year. The other 11 months it will be not normally crewed and robots will maintain that station.

“And it’s very similar to what we want to do with our not normally manned or not normally crewed offshore facilities and have robots there. So NASA see that opportunity as a way to trial robots in an environment on Earth, that to some degree has harsher conditions than what they will face.”

Gregory’s advice is to aim high when you go out and collaborate with others and seek a clear alignment of purpose.

“The purpose for us is really important in aligning partners, so whether or not it be with IBM or AWS or NASA, we need to figure out between us where is that alignment of purpose,” he said.

“For NASA it was very clear. They see Woodside as a great test bed of robotics in harsh environments doing very similar tasks that they would envisage them doing in the gateway project around the moon on the way to Mars.”

“Our people at Woodside who work in a robotics lab love that mission and what we can do to help them.

“And it turns out that from an aligned purpose, it also helps us in our business in being safer, more reliable and increased production.”