In the spinning world of digital disruption, complacency is the foe. Disruption makes you can ask ‘How did the Kodak, inventor of the digital camera, lose its way’ and ‘How did Google start in a garage and get to where it is today?’

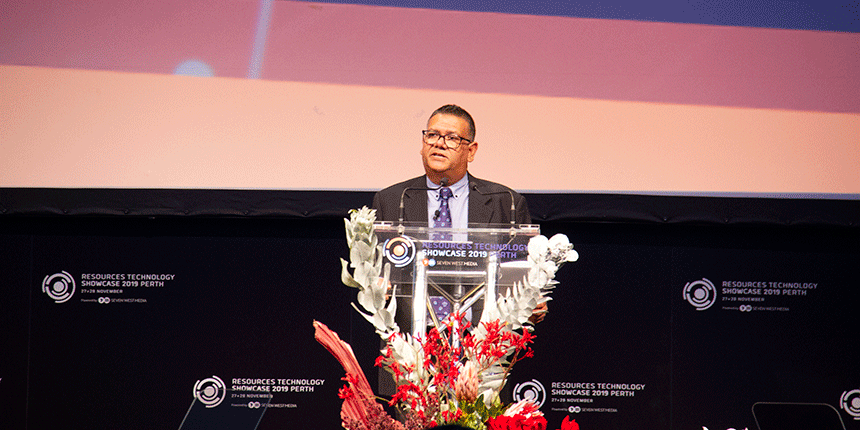

Head of group technical mining at Rio Tinto Santi Pal has pondered what it means to be the next Google and not the next Kodak.

Rio Tinto has a diverse portfolio of aluminium, copper and diamonds, energy and minerals and iron ore, employing 47,000 people in 35 countries.

“When it comes to digital disruption, complacency is actually our enemy,” Pal told Perth’s inaugural Resources Technology Showcase held by Seven West Media.

“We can never be fully content. We need to continue to learn and disrupt ourselves before someone else does. We must challenge everything, absolutely everything, we do.”

Not even being listed by Boston Consulting Group as the 49th most innovative company in the world in 2019 – the first time the global mining giant has appeared on the list – is enough.

Nor is being a pioneer of the industry, transforming workplaces with automation, including trucks, trains and drills, to drive productivity, lower costs and increase safety.

Pal says the only way to survive in the age or disruption is to consider two things: be prepared and aware of how your industry could possibly be disrupted; and learn to adapt because change is inevitable.

He outlined five priorities the 146-year-old company would continue to address to drive technology advancement into its mining plans, while striving to remain relevant.

These include:

- Safety

- Impact on environment

- Accelerating disruption

- Power of people and skills

- Partnerships

Safety

For Rio Tinto, automation is removing people from environments that expose them to harm, while monitoring technologies are improving the way major hazards including geotechnical and tailings.

In Mongolia, virtual reality is being used to train employees to work underground, while in Australia remote control devices, or crawlers, are being used for tank inspections which previously required multiple contractors and scaffolding.

“By using the remote crawlers to complete this task, we can now complete inspections safely in a fraction of the time,” Pal said.

“More importantly, it’s eliminated confined space activities and 20 days of working at heights, which will keep people safer and out of harm’s way.”

Environmental impact

Pal says the company has lofty goals to ensure it reduces its environmental footprint, which is absolutely essential.

In the next decade, Rio Tinto will aim to pursue decarbonisation, become more energy efficient and reduce the impacts of falling ore grade and waste by-products on the environment.

It has an objective of a zero-emission mining fleet by 2040

Accelerating disruption

Pal says increasing efficiency and flexibility will be crucial to optimising and accelerating disruption faster than it has in the past.

“We will also need to mine with more agility and in shorter time frames to more rapidly progress from discovery to operations,” he said.

“In exploration, we’ve taken an advanced approach to data and technology to improve our targeting, enabling us to uncover opportunities in areas that have been well explored by others.

It its iron ore operations in WA, Rio Tinto will have a 50 per cent autonomous fleet of haul trucks by 2022. It means 20 autonomous trucks will do the work of 23 operator trucks at about 15 per cent lower cost.

Power of people and skills

Crucial to the ability to transform the industry will be having a workforce skilled to support the future vision. Rio Tinto is therefore addressing: the changing skills requirements; difficulty attracting people with right skills to mining and metals; and increased competition for talent from other industries.

The company is building technical skills internally, as well as partnering externally with tafes and universities to address the changing skill requirements.

Partnerships

Pal said Rio Tinto had also realised that even though the company “knows a lot”, it does not “have all the answers” and will therefore seek to partner more often with external individuals and entrepreneurs.

When it launched its pioneer portal to call for ideas in 2019, it received 1000 views and many submissions within the first three weeks.

“We’re asking for original ideas from those that are ready to deploy now to address some of our challenges and productivity problems,” Pal said.

“For the brightest and the best ideas that come forward, we’ll provide the support with the funding, laboratory and research facilities, professional coaching or access to trial solutions at our operations. It’s a concept that’s relatively new to our industry but will radically change our approach to solving problems in the future.”

Pal said the industry was on the “precipice of the next frontier” with all that it had worked for the last hundred years to be turned upside down.

But with mining in Rio Tinto’s DNA, which is why the company has survived this long, he said the company realised that what it offered the market today may need to change for it to stay relevant in the future.

“Our industry like almost every other in the world is being improved but also challenged by new technologies and digital disruption on a daily basis,” he said.

“Some people see digital disruption as a negative trend, but we prefer to see it as a positive, aspirational force in our business.”